Table of Contents

Arc Extinction

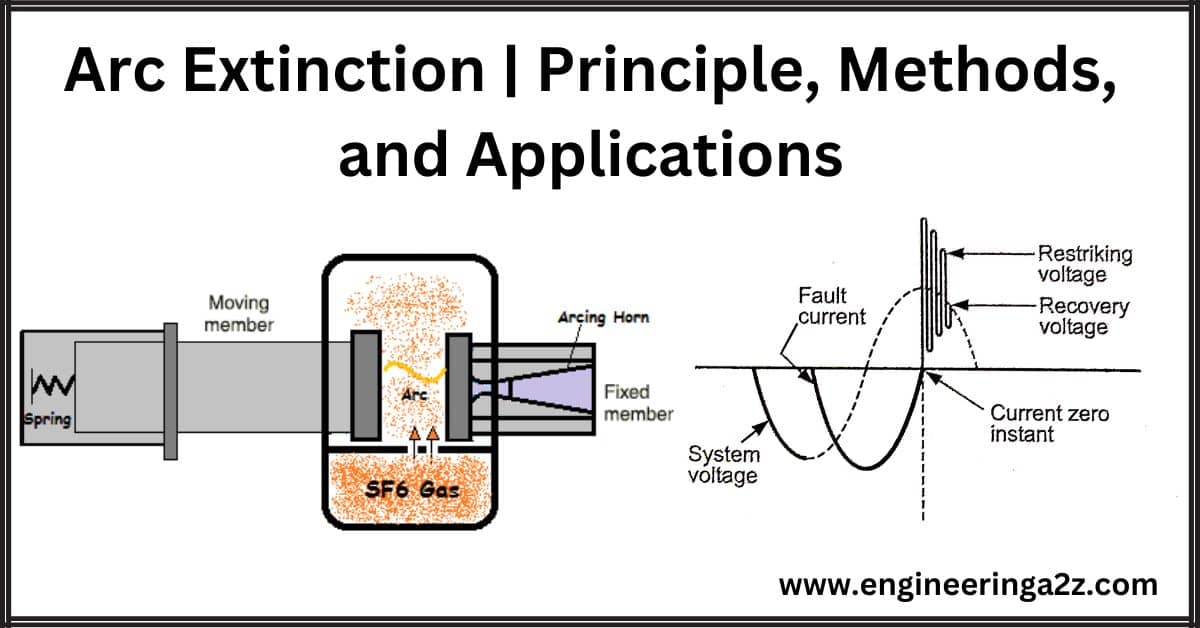

Arc extinction refers to the process of stopping or extinguishing an electric arc that forms between two conductive surfaces in high-voltage systems. When a voltage is applied across a gap, an electric arc is initiated, resulting in the flow of current through the gap. Arc extinction methods aim to interrupt this current flow by rapidly increasing the resistance of the arc path, causing it to cease.

Various techniques such as using circuit breakers, current zero-crossing, magnetic fields, and cooling gases are employed to achieve arc extinction. The successful extinction of arcs is crucial for electrical safety, preventing damage to equipment and ensuring the reliable operation of electrical systems.

Arc Phenomenon

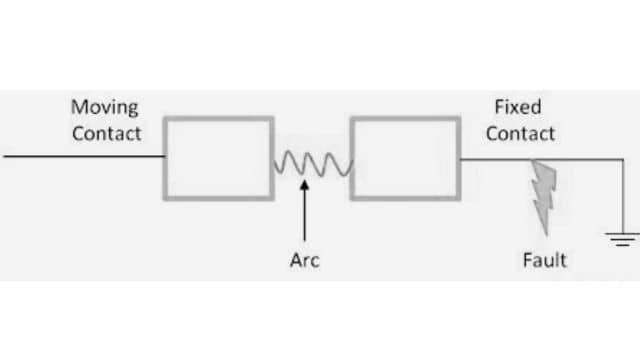

When a short circuit occurs, a heavy current flows through the contacts of the circuit breaker before they are opened by the protective system. At the instant when the connections begin to separate, the contact area decreases rapidly, and a significant fault current causes increased current density and hence a rise in temperature. The heat produced in the medium between contacts (usually the medium is oil or air) is sufficient to ionize the air or vapourize and ionize the oil.

The ionized air or vapour acts as a conductor and an arc is struck between the contacts. The potential difference between the contacts is quite small and is just sufficient to maintain the arc. The arc provides a low resistance path and consequently, the current in the circuit remains uninterrupted so long as the arc exists.

In circuit breakers, the contact space is ionized by the following causes:

- Thermal ionization of the gas.

- Ionization by collision of particles.

- Thermal emission from the surface of contacts.

- Secondary emission from the surface of contacts.

- Field emission from the surface of contacts.

During the arcing period, the current flowing between the contacts depends upon the arc resistance. The greater the arc resistance, the smaller the current that flows between the contacts. The arc resistance depends upon the following factors:

(i) Degree of ionization: The arc resistance increases with the decrease in the number of ionized particles between the contacts.

(ii) Length of the arc: The arc resistance increases with the length of the arc i.e., separation of contacts.

(iii) Cross-section of are: The arc resistance increases with the decrease in the area of the cross-section of the arc.

Principles of Arc-Extinction

Prior to discussing the methods of arc extinction, it is essential to scrutinize the factors accountable for the maintenance of the arc between the contacts. These are:

(i) potential differences between the contacts

(ii) ionized particles between contacts.

Taking these into account,

(i) When the contacts have a small separation, the potential difference between them is sufficient to maintain the arc. One way to extinguish the arc is to separate the contacts to such a distance that the potential difference becomes insufficient to maintain the arc. However, this method is impracticable in high voltage systems where separation of contacts is many meters may be required.

(ii) The ionized particles between the contacts tend to maintain the arc. If the arc path is deionized, the arc extinction will be facilitated. It may be achieved by cooling the area or by removing the ionized particles from the space between the contacts.

Deionization of particles is carried out by one of the following methods:

- Recombination

- Diffusion

- Conduction of heat.

Methods of Arc Extinction

There are three basic methods of arc extinction in circuit breakers as follows:

- High resistance method

- Low resistance method or current zero method

- Artificial current zero method.

- High resistance method: In the high resistance method, the arc resistance is made to increase gradually with time so that the current is reduced to a value insufficient to maintain the arc. Consequently, the current is interrupted and the arc is extinguished without creating any damage to the circuit breaker compartment. The principal disadvantage of this method is that enormous energy is dissipated in the arc. So, it is employed in d.c. circuit breaker and low-capacity a.c. circuit breakers.

The following are the different ways to increase the resistance of the arc medium:

(a) Increase the length of the arc: The resistance of the arc is directly proportional to the length of the arc. The length of the arc can be increased by increasing the gap between contacts.

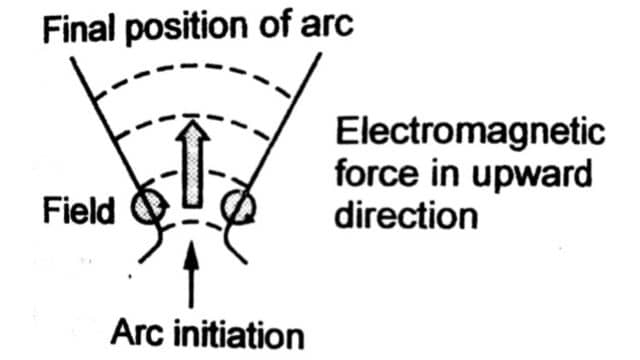

(b) Arc cooling method: Cooling arc medium helps in the deionization of the medium between the contacts. It increases arc resistance. Efficient cooling is obtained by a gas blast directed along the arc.

(c) Reducing the cross-section area of the area: If the area of the cross-section of the arc is reduced, then the voltage necessary to maintain the arc is increased. So, the resistance of the arc path is increased. The cross-section area of the arc can be reduced by letting the area pass through the smaller area of contacts compared to a wide area.

(d) Arc splitting method: The resistance of the arc can be increased by splitting the arc into a number of smaller arcs in series. Each of these arcs experiences the effect of lengthening and cooling. The arc may be split by introducing some conducting plate between the contacts of the circuit breaker.

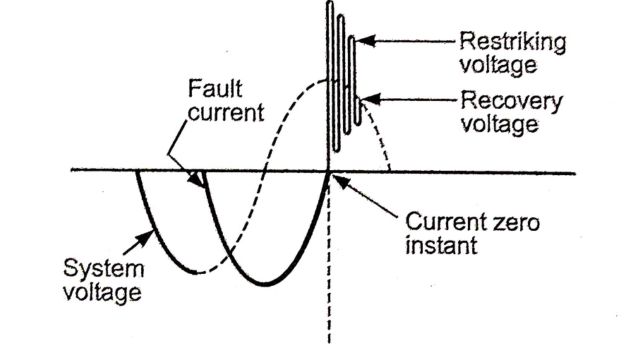

- Low resistance method or current zero methods: This method is employed for arc extinction in a.c. circuits only. In this method, the arc resistance is kept low until the current magnitude becomes zero where the arc extinction occurs naturally and is prevented from restriking instead of the rising voltage across the contacts.

In an a.c. the system, the current drops to zero after every half cycle. At every current zero, the arc extinguishes for a brief moment. The medium between the contacts contains ions and electrons so that they have small dielectric strength and can be easily broken down by the rising contact voltage known as restriking voltage. If such a breakdown occurs, the arc will persist for another half cycle. If immediately after current zero, the dielectric strength of the medium between the contacts is built up more rapidly than the voltage across the contacts, the arc fails to restrike and the current will be interrupted. The rapid increase of dielectric strength of the medium near current zero is achieved by:

(a) recombining the ionized particles in the contact medium into neutral molecules.

(b) sweeping the ionized particles away from the medium and replacing them with new ones. So, it is clear from the above discussion that the real problem in a c. is interruption is to rapidly deionize the medium between contacts as soon as the current becomes zero so that the rising contact voltage or restriking voltage cannot break down the space between the contacts. Rapid de-ionization can be achieved by the following methods:

(a) Increase the length of the gap: The dielectric strength of the medium is proportional to the length of the contact gap. So, by opening the contacts rapidly, the higher dielectric strength of the medium can be obtained.

(b) High pressure: If the pressure of ionized particles in the vicinity of the arc is increased, then the density of the particles constituting the discharge also increases. This increased density of particles causes a higher rate of de-ionization which increases the dielectric strength between the contacts.

(c) Cooling: Natural combination of ionized particles takes place more rapidly if they are allowed to cool. So, in this way, the dielectric strength of the arc medium between the contacts can be increased by cooling the arc.

(d) Blast effect: If ionized particles between the contacts are swept away and replaced by unionized particles, the dielectric strength of the medium can be increased considerably. This can be achieved by a gas blast directed along the discharge or by forcing oil into the contact space.

Several theories have been postulated to explain arc interruption. For example, Slepian’s theory and Energy Balance theory.

- Artificial current zero methods:

In HVDC switching devices, the artificial current zero method is used to interrupt DC arcs. Current zeroes are generated in the LC oscillatory circuit within the circuit breaker when opening the contacts. The breaker extinguishes the arc, while a ZnO arrester limits transient recovery voltage and absorbs energy. Unlike AC current, DC current lacks natural zeroes. Oscillations occur during circuit breaking due to the current in the capacitor and parallel reactor, resulting in multiple current zeroes. The breaker interrupts the arc at one of these zeroes.

Advantages of Arc Extinction

- Safety: Arc extinction techniques ensure the safety of both personnel and equipment by rapidly interrupting and extinguishing electric arcs. By preventing prolonged arcing, the risk of electrical shocks, fires, and explosions is significantly reduced.

- Equipment Protection: Arcs can cause damage to electrical components, including switches, circuit breakers, and other connected devices. Effective arc extinction prevents excessive heat buildup, electrical damage, and wear, thereby extending the lifespan of equipment and reducing maintenance costs.

- Reliable Operation: Arcs can disrupt the proper functioning of electrical systems and lead to power interruptions or outages. Efficient arc extinction methods help maintain the continuity and reliability of power supply, minimizing downtime and ensuring smooth operations in various industries such as manufacturing, transportation, and utilities.

Disadvantages of Arc Extinction

- Higher initial costs and ongoing maintenance expenses.

- Increased complexity in system design and operation.

Application of Arc Extinction

- Electrical Power Distribution: Arc extinction is crucial in circuit breakers and switchgear to protect power distribution networks from arc faults and ensure reliable power supply.

- Industrial Equipment: Arc extinction is employed in machinery, motors, and control panels to prevent electrical arcing, safeguard equipment, and maintain operational efficiency.

- Transportation Systems: Arc extinction techniques are utilized in railways, aviation, and electric vehicles to ensure safe and reliable operation by preventing electrical arcs in critical components.

- Renewable Energy: Arc extinction is essential in solar power systems, wind turbines, and energy storage systems to mitigate arc-related hazards and protect electrical infrastructure.

Frequently Asked Questions (FAQs)

What is arc extinction?

Arc extinction is the process of stopping or extinguishing an electric arc that occurs in high-voltage systems.

What is arc voltage?

The voltage that appears across the contacts of the circuit breaker during the arcing period is called arc voltage.

What is restriking voltage?

The transient voltage that appears across the contacts at or near current zero during the arcing period is called restriking voltage.

What is recovery voltage?

The normal frequency r.m.s. voltage that appears across the contacts of the circuit breaker immediately after final arc extinction is called recovery voltage.

Read Also:

- Stand Alone PV System | Schematics and its Components

- Characteristics and Advantages of A.C. Over D.C. and Vice Versa

- Electric Traction | Speed-Time Curve

- Computer-Aided Electrical Machine Design Notes

- Globalisation | Impacts of Globalisation

Leave a Reply