Table of Contents

Piezoresistive

Piezoresistive materials are substances that exhibit changes in electrical resistance when subjected to mechanical stress or strain. This property makes them particularly useful in sensor applications for measuring pressure, force, acceleration, and other physical quantities.

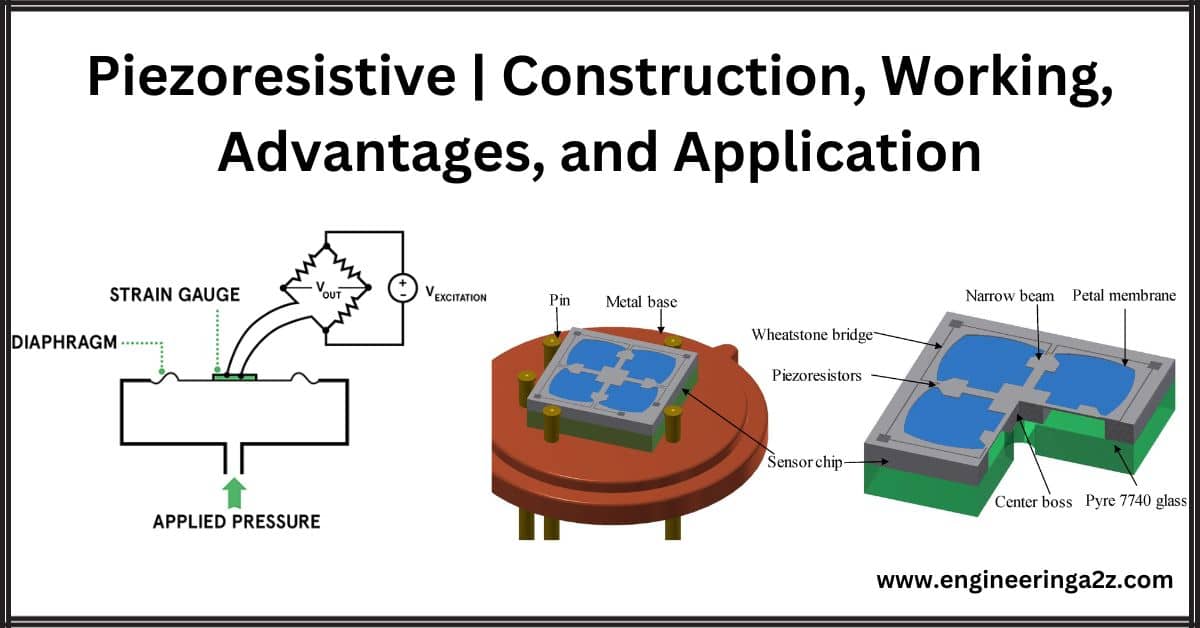

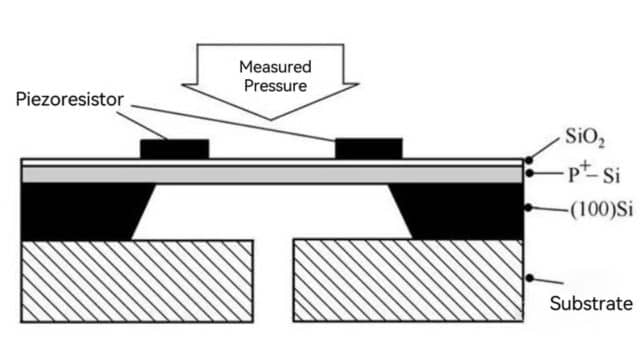

Construction of Piezoresistive

Piezoresistive sensors are intricately constructed devices designed to measure pressure by leveraging the changes in electrical resistance resulting from mechanical strain. Typically, these sensors are built upon a silicon substrate due to its favorable mechanical properties and compatibility with microfabrication methods. The process involves depositing a thin layer of resistive material, often doped silicon, onto the substrate using techniques like sputtering or chemical vapour deposition.

This thin film acts as the strain-sensitive element that alters its electrical resistance when subjected to pressure. Patterning techniques, such as photolithography and etching, sculpt the resistive material into specific configurations, forming the sensor’s sensing structures. Electrical connections are established to the resistive elements, enabling the measurement of resistance variations induced by pressure changes. Protective encapsulation shields the sensor from environmental influences and physical harm. Ultimately, the sensor’s electrical signals are processed by associated circuitry to translate resistance alterations into meaningful pressure readings, culminating in a meticulously crafted device with precise pressure measurement capabilities.

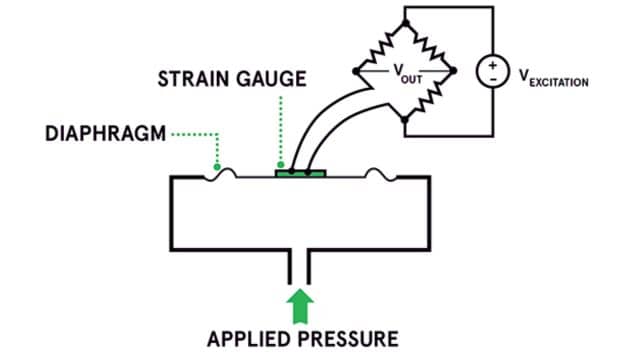

Working Principle of Piezoresistive Sensor

A strain gauge is like a super sensitive translator: it turns any tiny changes in how something stretches or squishes into an electrical signal. There are two main types: metal ones and semiconductor ones.

Metal strain gauges work by changing their resistance when the material they’re stuck to gets stretched or compressed. So, when the thing they’re attached to feels some kind of force or stress, the strain gauge changes shape too, altering its resistance. This change in resistance causes a change in voltage across the gauge. To make sense of this tiny signal, we use a bunch of strain gauges together in what’s called a strain bridge. Then we use special amplifiers to boost the signal and send it to a circuit that either shows us data or makes something happen, like controlling a machine.

Application of Piezoresistive Sensors

- Wide Applications: These sensors are used in various fields like aerospace, aviation, navigation, petrochemicals, and more.

- Precision Pressure Measurement: They’re perfect for accurately measuring static, dynamic, and local pressures in aerospace, especially in planes and engines.

- Specific Uses: They help measure things like airflow over helicopter wings, engine distortion, fluctuating pressures, and even tiny movements in wings.

- High-Temperature Operations: Specially designed sensors can handle extreme temperatures, like above 500℃ in jet engines.

- Precision in Aerospace: In aircraft, they’re crucial for measuring central pressures with very high precision (0.05%) for systems like Boeing’s atmospheric data measurement.

- Testing Tools: Used in scaled-down wind tunnel models for testing at the inlet and engine intake lines.

- Diverse Uses Beyond Aerospace: They’re also used to measure explosion pressures, monitor automobile engine performance, in weapon systems, oil well pressure, underground cable checks, and more.

- Future Growth: With advancements in technology like microelectronics and computers, these sensors are expected to become even more widespread and advanced.

Advantages of Piezoresistive

Piezoresistive sensors offer several advantages:

- Robustness: They are known for their durability and resilience. They can withstand harsh conditions and maintain accuracy over time, making them reliable in demanding environments.

- Stability: These sensors exhibit stable performance and calibration over extended periods. Their consistent output ensures reliable and accurate measurements.

- Precision: Piezoresistive sensors provide high precision in measuring pressures, both static and dynamic. This accuracy is crucial in various industries, especially in aerospace and engineering.

- Versatility: They can be used across a wide range of applications due to their ability to measure various pressure types, from local pressures to whole pressure fields.

Disadvantages of Piezoresistive

- Power Consumption: Compared to certain other types of pressure sensors, piezoresistive sensors tend to consume more power. This higher power requirement might not be ideal for battery-powered devices or portable systems, limiting their use in such applications.

- Temperature Limitations: Depending on the materials used, some piezoresistive sensors might have temperature limitations. Silicon strain gauges, for instance, are typically limited to operating temperatures below 100°C, which might restrict their use in high-temperature environments.

- Sensitivity to External Factors: They can be sensitive to external factors such as mechanical shocks, vibrations, or electromagnetic interference, potentially affecting their accuracy in certain situations.

- Cost: Designing and manufacturing piezoresistive sensors with high precision and reliability can be costly, impacting their affordability compared to some other sensor types.

Frequently Asked Questions (FAQs)

What is a piezoresistive effect?

The piezoresistive effect is the change in electrical resistance within materials like silicon or semiconductors when subjected to mechanical strain or pressure, essential in piezoresistive sensors for pressure measurement.

What are the components of a piezoresistive pressure sensor?

A piezoresistive pressure sensor typically includes a substrate (often silicon), strain-sensitive resistors, electrical connections, protective packaging, and associated signal-processing components for pressure measurement.

What are piezoresistive materials?

Piezoresistive materials, like doped silicon, germanium, or certain semiconductor compounds, exhibit changes in electrical resistance when subjected to mechanical stress or pressure, crucial in piezoresistive sensors.

What is a piezoresistive sensor used for?

Piezoresistive sensors measure pressure by detecting changes in electrical resistance due to mechanical strain, widely employed in industries like aerospace, automotive, biomedical, and various engineering applications.

Read Also:

- Block Diagram Reduction | Control System

- Norton’s Theorem

- Circuit Theorem | Thevenin’s Theorem

- Block Diagram Reduction | Control System

Leave a Reply