Table of Contents

Combined Gas and Steam Power Plant

As we know that Gas turbine plant are generally used for supplying peak loads with other type of power plant (Steam and Hydro power plant) because gas turbine plant as a quick starting and good response characteristics. The temperature of gas turbine exhaust lies between 400 to 500°C temperature and contains about 16% of O2 , 70% of initial quantity of energy carried away by the exhaust gases. Due to large exhaust loss, the gas turbine plant has a low thermal efficiency about 30% .

Fuel used in Gas turbine power is costly therefore cost power generated by a gas turbine plant for utility system is high. To overcome this low cycle efficiency a gas turbine plant may be used in conjunction with a steam turbine plant in an utility based load station to offer the advantages of gas turbine as quick starting and stopping and permit flexible operation of combine plant over wide range of loss.

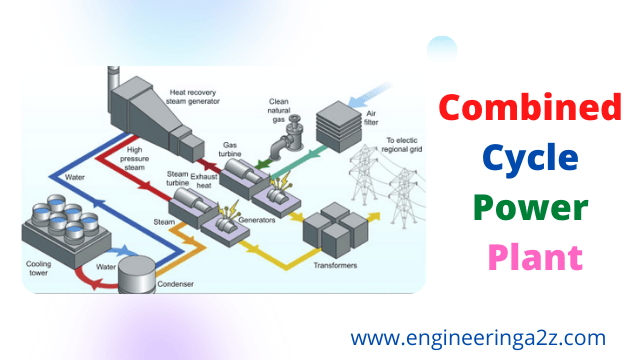

Working of Combined Cycle Power Plant

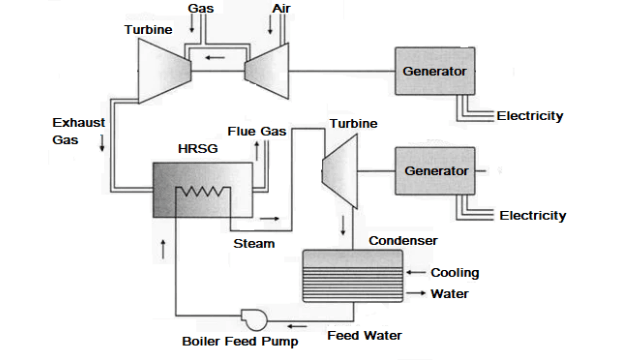

A combine cycle as the name implies is a combination of two cycle operating at different temperature each of which could operate independently. The heat rejection by the higher temperature cycle ( topping cycle –Brayton cycle) is re-called and used by the lower temperature cycle (Bottom cycle –Rankine cycle) to produce additional power to realise and improve overall efficiency.

Topping cycle may be Brayton or Rankine cycle but bottom cycle have all being Rankine cycle in all the cases. The gases coming from the gas turbine has a temperature about 400 to 500°C temperature . Hence it carries large amount of energy. This energy goes as a waste if it is rejected to atmosphere. This waste heat energy may be utilized to produce steam in a heat recovery steam generator (HRSG) and may be expended in the steam turbine to develop additional power. This combination is termed as steam and gas turbine combination cycle power plant. After the expansion the gases in gas turbine the exhaust gases passes through HRSG that generator steam at one or more pressure through superheater.

The steam is fed to the steam turbine that drives an electric generator. In this arrangement the gas turbine can be decoupled from the operation of steam turbine allowing for steam turbine shutdown with continued gas turbine operation. This combine cycle efficiency ranges from 47% to 60% as compared to 30% to 40% of conventional steam gas turbine power plant. It is desirable that exhaust gases temperature of gas turbine should be above 570°C , otherwise the steam cycle will be inefficient resulting in lower combine cycle efficiency.

Advantages of Combined Cycle Power Plant

- Combined cycle power plant has high efficiency than other power plants

- This power plant has less vibration and having less moving parts .

- It emits low toxic emissions.

- It runs at high operating speed

- It operates on various loads.

Disadvantages of Combined Cycle Power Plant

- It has high operating cost.

- It takes long time to start-up.

- It is less responsive to power demands.

- It pollutes the environment.

Leave a Reply