Table of Contents

Discharge Lamp

Incandescent lamps have a very low lumens output. Moreover, they give yellow light, which creates strain in our eyes. Discharge lamps have high production and produce a light that is pleasing to the eyes.

The discharge lamps have two electrodes in a glass (or quartz) envelope with a gas. When electrodes are given a supply, the light is produced through gas discharge. (ionization).

The color of light produced depends upon the gas or vapor filled in the lamp.

Classification Of Discharge Lamps

The discharge lamps can be classified into two categories only.

- The lamps which emit the light of original color produced by the discharge eg.. (1) Mercury lamp (2) Sodium lamp (3) Neon lamp

- Lamps that employ the principle of fluorescence Le. A phosphor material is coated on the inner walls of the lamp. The color of the light coming out of the lamp depends upon the color of the phosphor irrespective of the original color of discharge e.g. Fluorescent tubes.

There is another classification of discharge lamps.

- The hot cathode lamps can work on a standard low-voltage supply. The cathode in the form of a heater element, is heated to emit electrons as is done in radio valves or it may be maintained in the incandescent state by ionic bombardment. A sodium vapor lamp is one example of a hot cathode lamp.

- The cold cathode lamps use a high voltage supply across the electrodes. The potential drop at the cathode surface is large (100-200V), which is sufficient to emit a large number of electrons from it. The current in the lamp is kept low, and the resistance of the luminous column is high. A transformer provides a high-voltage supply to the lamp. Neon light is an example of a cold cathode lamp.

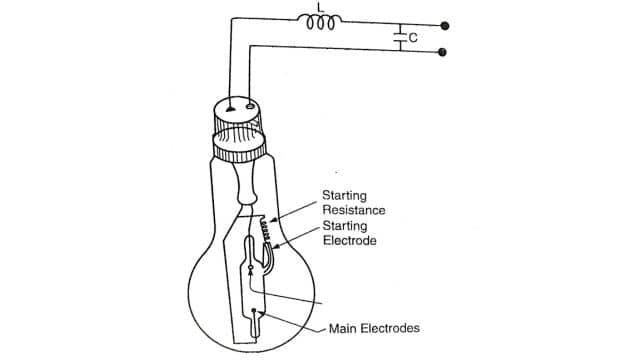

1. Mercury Vapour Lamp

The lamp consists of two tubes. The inner tube contains neon or Argon gas with some quantity of mercury with low pressure. This tube is made of hard glass to bear the bombardment of ions during the ionization process. The inner tube contains two electrodes of oxide-coated coils. These are called Main Electrodes. There are also Auxillary Electrodes.

The inner tube is enclosed in an outer tube made up of ordinary glass. The space between the tubes is evacuated to prevent heat loss due to convictions.

When supply is given, an electric field is set up between the starting electrode and the nearby main electrode. This causes discharge. It vaporizes the mercury drops in the inner tube. It takes a few minutes to vaporize all the mercury and the lamp attains full brightness.

A choke is used to control the current to safe value and a capacitor is used to improve the P.F. These lamps are available from 80 to 1000 W and operated in vertical position otherwise the inner tube will burn. The efficiency of these lamps is about 40 Im per watt and life is about 5000 hrs.

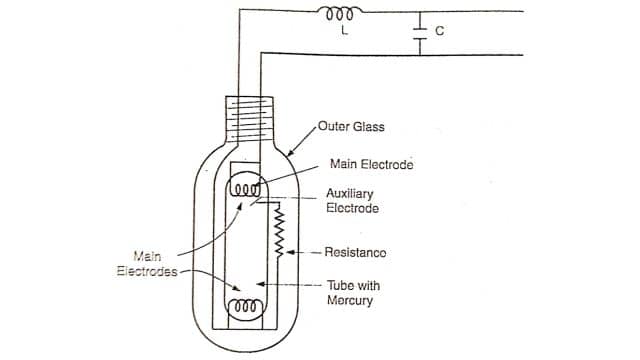

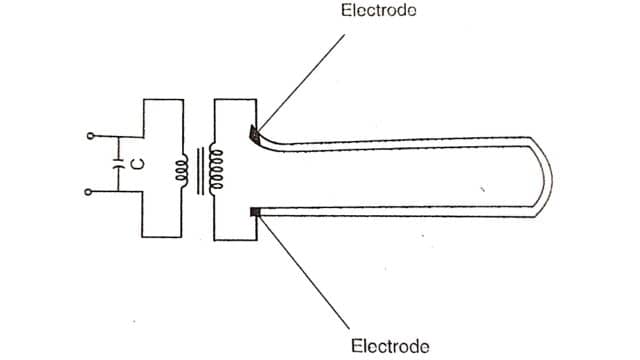

2. Sodium Vapour Lamp

The sodium vapor lamp is a type of light source that has become more popular than the mercury vapor lamp because it produces a high amount of bright light.

It’s made up of two tubes: an inner and an outer one. The inner tube is U-shaped and made from a special glass that can handle hot sodium without getting damaged. This inner tube contains a small amount of metallic sodium. There are also neon gas and electrodes connected to its base. The outer tube is a glass tube with two layers to keep the heat in. To work properly, the sodium lamp needs to be placed horizontally and treated carefully. If it breaks, the sodium inside can catch fire when it touches the air.

For starting the lamp, a device called a choke is used, and to control the lamp’s power, an autotransformer called a ballast is used. The ballast needs to have some energy loss, which is achieved by making it leak some electricity. The light emitted by this lamp is mainly at a specific wavelength, around 5890 angstroms. Our eyes are most sensitive to this wavelength, which is why it’s efficient for lighting. The lamp’s theoretical efficiency can be very high, around 475 lumens per watt, but due to various losses, its practical efficiency is lower, usually between 40 to 50 lumens per watt.

The light produced by the sodium lamp is a single color, orange-yellow, which can make things look somewhat gray. Because of this, these lamps are mainly used for outdoor street lighting. It takes about thirty minutes for the lamp to reach its maximum brightness. To improve its performance, a capacitor can be added. These lamps usually last around 3000 hours and are not affected much by changes in voltage.

The lamp’s life comes to an end when:

- The filament breaks or burns out.

- The cathode stops emitting electrons.

- Sodium particles gather on one side of the tube.

- The tube turns black due to sodium reacting with the glass.

Because a long path for the light is needed, the tube is bent into a U shape. These lamps are only suitable for AC power supplies. Due to the way they’re built, their power factor drops to 0.3, so a capacitor is added to improve it. They come in different power ratings like 45, 60, 85, and 140 watts.

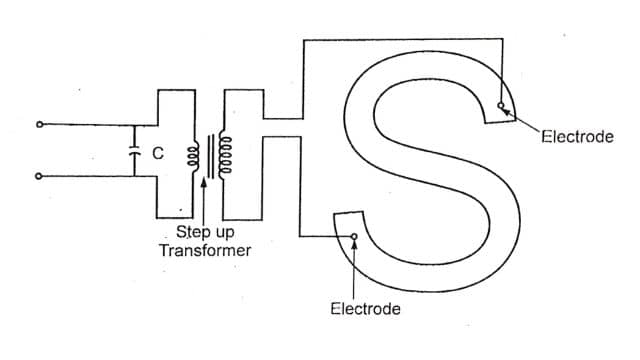

3. Neon Lamps

This is a type of lamp known as a “cold cathode lamp.” It comes in various lengths, up to 10 meters, and can be shaped during manufacturing but can’t be reshaped afterward.

The lamp is essentially a long glass tube, typically cylindrical, with steel or copper electrodes inside. This tube is filled with neon gas.

The tube’s diameter can vary, typically from 10 to 30 millimeters, and it carries a current ranging from 25 to 150 milliamps. It requires a voltage between 300 to 1000 volts for every meter of its length. To start the lamp, you need roughly double the normal operating voltage. To achieve this, a special transformer with high reactance (resistance to changes in current) is used. To ensure safety, the voltage at any point in the lamp should not exceed 5000 volts above ground. For safety reasons, the midpoint of the transformer’s secondary winding is connected to the ground.

These lamps are called “cold cathode lamps” because they operate at a very low temperature, around 200 degrees Celsius. They’re commonly used for advertising signs, where each letter has two electrodes at its ends to create the desired lighting effect.

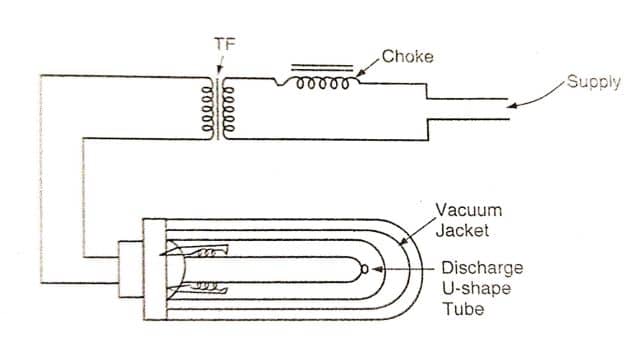

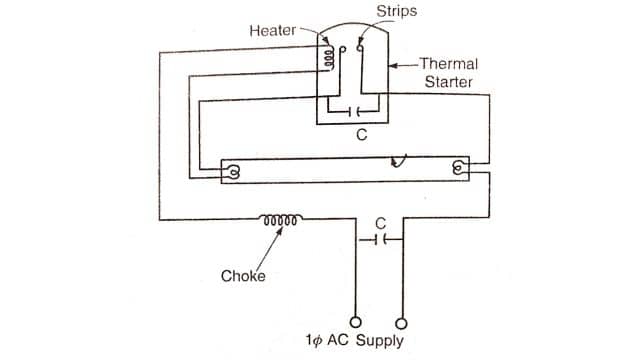

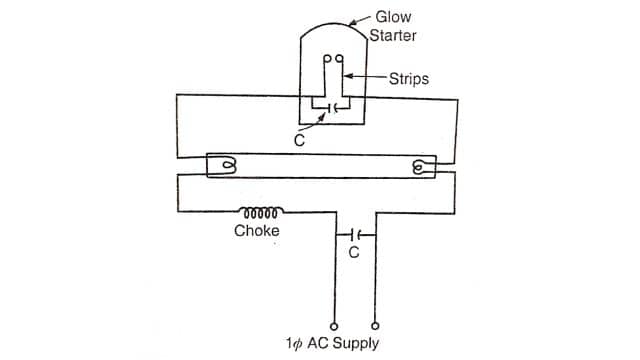

4. Fluorescent Tubes

The tube consists of a glass tube of 25 mm diameter and 0.6 m. 1.2 m and 15 min length. The tube contains argon gas which is an inert gas at a low pressure of 2.5 mm and one or two drops of mercury. The inner walls of the tube are coated with fluorescent powder. The phosphor material transforms short waves of invisible radiations into visible light. By using different phosphor materials, different colored light may be obtained.

The tube is provided at its ends with electrodes coated with some electron Cadmiumemissive material like Tungsten. A choke is connected in series which gives a high voltage impulse that is required for starting the tube and after starting it acts as Ballast. A starter is provided which helps in the starting of the tube. A capacitor is used across the supply which improves P.F.

Starters: The starter may be of two types

- Thermal Starter

- Glow starter

(1) Thermal starter: This setup has two metal strips and a coil that heats up. The metal strips are normally touched when the lamp isn’t on. When you turn on the power, the lamp’s electrodes (the parts inside that give off light) get connected in a chain with this setup. This creates a really strong current that heats up the electrodes until they’re glowing.

At the same time, the coil in the setup heats the metal strips, causing them to move apart and break the lamp’s circuit. This break in the circuit makes a big surge of electricity, which makes a spark between the lamp’s electrodes. This spark keeps going because of the lamp’s power. The positive parts of the lamp’s ions hit the electrodes, which keeps them at the right temperature for the lamp to work. This kind of starter isn’t used much because it’s complex and not very efficient. Usually, simpler glow starters are used instead.

(2) Glow Starter: This setup uses two metal strips inside a glass tube. Normally, these strips are not touching. When you turn on the power, the full voltage reaches these strips and a gentle glowing happens between them. This glow makes the strips warm up and touch each other.

When the strips touch, a strong electric current starts flowing through the tube’s filaments, making them really hot and causing the nearby gas (Argon) to become charged. After a second or two, the starter’s strips cool down, and they open up again. This creates a gap between them.

When the gap is there, a switch in line with a part called a choke opens up. This creates a quick high voltage in the tube’s filaments, which makes a flash of light inside the tube. This flash helps the tube to start glowing on its own.

Once the tube is lit up and working, the starter is not needed anymore, and the tube only needs 115 volts to keep shining.

The fluorescent tube suffers from

(a) Radio Interference: Whenever a tube is operated, an arc is produced in the starter. This affects electronics products nearby (say TV). This is called radio interference. To minimize this, a capacitor (0.05 uf) is connected across the strips of the starter. The capacitor gets charged due to the arc, and radio interference is controlled.

(b) Stroboscopic effect: After every half-cycle, the current in an AC circuit is zero. At that instant, the tube remains off. This is called the stroboscopic effect. In industries, this phenomenon may lead to an accident as, at this instant, bodies may appear to be stationary or their actual speed or position cannot be ascertained.

Therefore, it is advisable not to operate a single tube, always, a twin tube set should be used in parallel. In this arrangement at every instant, one of the two tubes is always on.

Characteristics of discharge lamps

The discharge lamps have the following characteristics written below:

- They can be used in a certain position or Horizontally/vertically.

- They operate at low P.F. (about 0.5).

- They are costly. Special devices like Ballasts and transformers are needed to operate these lamps satisfactorily.

- They take a starting time to give full output.

- Light is produced through the discharge (Ionisation) of the filled gas.

Frequently Asked Questions (FAQs)

What is a Discharge Lamp?

A discharge lamp is a type of light source that’s made up of a glass or quartz tube containing a specific gas and often a metal vapor. When electricity flows through this gas and vapor mixture, it creates light or ultraviolet radiation. In simple terms, the lamp’s electricity makes the gas and vapor glow, producing the light we see or even invisible ultraviolet light.

What is the color of the Discharge Lamp?

The color of the light that a discharge lamp emits depends on the specific gas or vapor inside it. Different gases produce different colors when they’re excited by the electrical current.

What are the examples of Discharge lamps?

Fluorescent, sodium vapor, neon, mercury vapor, metal halide, xenon arc, argon, and krypton lamps are examples of discharge lamps.

Read Also:

- Starting Methods of 3-Phase Induction Motor

- DC Generator | Construction and Working Principle

- Stand Alone PV System | Schematics and its Components

- Earth Leakage Circuit Breaker (ELCB) | Types, Working Principle, And Construction

- PMMC Instrument || Construction & Working || Advantages & Disadvantages

- Quality Systems | Types, Benefits, and Need For Standardization

Leave a Reply