Table of Contents

What is Earthing

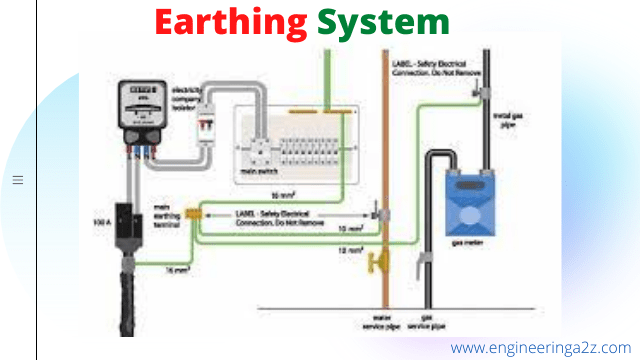

The meaning of the term earthing is to connect the electrical equipment to the general mass of earth by lead of negligible resistance. Selection of earthing is very important for the safety of human life, houses and machines. This brings the body of the electrical equipment to zero potential and thus, will avoid the shock to the operator. In case of earth fault, heavy current flow through the circuit, the circuit’s fuse melts out or put down the MCB of the circuit and faulty circuit will be disconnected from the supply.

Simply we can say that it the process of connecting the non-current carrying metallic parts of an electrical equipment or the neutral of a supply system to the earth is known as earthing.

Importance of Earthing

- Provide a surface around and under a sub-station, which would be at a uniform potential and as near to zero or absolute earth potential as possible.

- Ensure people in surrounding area are not exposed to electric shock.

- Better performance of the electrical system.

- To protect the human being from disability or death from shock in case the human body comes into the contact with the frame of any electrical machinery, appliance or component, which is electrically charged due to leakage current or fault.

- To maintain the line voltage constant

- To serve as the return conductor for telephone and fraction work.

Types of Earthing

Earthing is achieved by connecting the electrical appliances or components to earth by employing a good conductor called earth electrode. This ensures very low resistance path from appliance to the earth. The two important methods of earthing are

- Plate Earthing

- Pipe Earthing

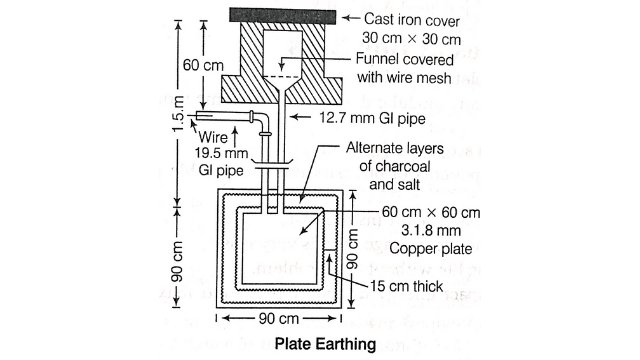

Plate Earthing

In plate earthing, the looping earth wire is bolted effectively with the earth plate made up of copper size 60 cm x 60 cm x 3.18 mm (2’x 2’x1/4″) and embedded 3 m in ground. The plate earthing can also be provided by Galvanised Iron (GI) plate having the dimensions 60 cm x 60 cm x 6.3 mm.

Copper plates of 30 cm x 30 cm are found to be most effective earth electrodes and are not affected by the soil moisture i.e., these do not get rusted. But on account of its high material cost, galvanised iron plates are preferred and usually used for normal work.

In case the coil resistivity is high, the plate should be placed vertically in ground at a higher depth. A line diagram showing the plate earthing system is shown in figure

The plate is kept with its face vertical and so arranged that it is embedded in an alternate layer of coke and salt for a minimum thickness of about 15 cm. The coke salt decreases the earth resistance. It should be remembered that the nuts and bolts of size 50 mm x 30 cm must be of copper for copper plate and should be GI for GI plates. A funnel with mesh can also be provided to pour water.

The conductivity, i.e., earthing efficiency increases with the increase of plate area and depth of embedding. Its only disadvantage is that discontinuity of earth wire and plate below the earth cannot be observed physically, hence, is misleading and sometimes result in heavy loss in case of any fault.4

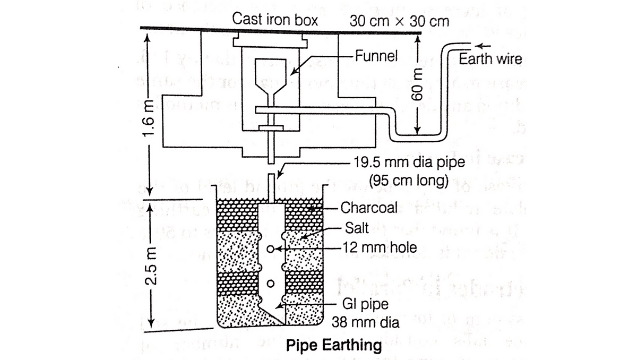

Pipe Earthing

In this system of earthing, GI pipe of 38 mm diameter and 2 m (7 ft) length are used. A pit of about 40 cm² area and 4 to 5 m depth is dug in the soil. The earth wires of 8 SWG of GI are fastened to the top section of the pipe with nut bolts. The pit area around the GI pipes is filled with salt, charcoal and coal mixture for improving the soil condition and efficiency of the earthing system.

After placing the electrode in the pit, layers of charcoal and salt are used to fill the space around it. The electrode can be connected GI pipe of 12.7 mm diameter for carrying GI earth wire. The earth electrode used may be copper plate having a dimension 60 cm x 60 cm x 3.18 mm. In case of GI plate, the dimension of plate is 60 cm x 60 cm x 6.36 mm.

The contact surface area of GI pipe with soil is more in comparison to the plate because of its circular section and hence can take up heavy leakage current for the same electrode size. The earth wire connection with the GI pipe being above the ground level can be checked for carrying out continuity tests as and when desired while in plate-earthing it is difficult. It is an advantage over the plate-earthing.

As safety from electricity and over voltage protection etc., are important factors due to which earthing concepts have been developed.

Reduction in Earth’s Resistance

The purpose of the earthing is mainly for safety of human life. If safety devices, circuit breakers, fuses are not working properly during fault in wiring, than safety of human life is not possible. Thus, the resistance of earthing should be minimum to ensure the working of safety devices.

By Pouring Water

The dampness of the soil and coal salt paste depends upon the atmospheric conditions. In summer season. fresh salt water should be poured through the pipe over the coal bed.

The soil resistance can be reduced by two additional steps:

Increase in Plate Area

In case of increase in plate area, the decrease of resistance value is not in direct proportion to the area. It is found that to reduce the resistance value by 1/6, the increase in area is 36 time more than for the same soil condition and depth of electrode. So this method is not used.

Increase in Depth

The increase of depth below the ground level of the same plate reduces the resistivity of the earthing system. It is found that the plate area reduces to 50% when the depth is doubled for the soil resistance.

Electrodes in Parallel

In this system of lowering earth resistance, the soil resistance falls considerably as the number of electrodes interconnected in parallel are increased for same depth.

R₁ and R₂ etc., are earth resistance of each electrode then the total earth resistance of the system.

Total Resistance,1/R=1/R₁+1/R₂

Frequently Asked Questions (FAQs)

-

Why earthing is required?

Earthing is very important for the safety of human life, houses and machines. This brings the body of the electrical equipment to zero potential and thus, will avoid the shock to the operator.

-

What are the materials used for earthing?

Earthing wires are primarily composed of high-quality copper or GI, which can be utilised in a variety of electrical, electronic, and automotive devices and alternate layer of charcoal and salt. The charcoal-salt mixture decreases the earth resistance and water.

-

Which earthing is commonly used in India?

Pipe earthing is a common earthing technology in India that works with any soil type. The pit area around the GI pipes is filled with salt, charcoal and coal mixture for improving the soil condition and efficiency of the earthing system.

Leave a Reply